In the world of advanced manufacturing, CNC laser cutting service as well as CNC punching work has changed the way industries look at metallic fabrication and material processing. These are the modern technologies which are mandatory for the organizations having stringent and ultra-ordinate needs in aspects of perfection, speed, and immaculate performance in automobile, aeronautics, electronics and construction industries and more.

What is CNC Laser cutting?

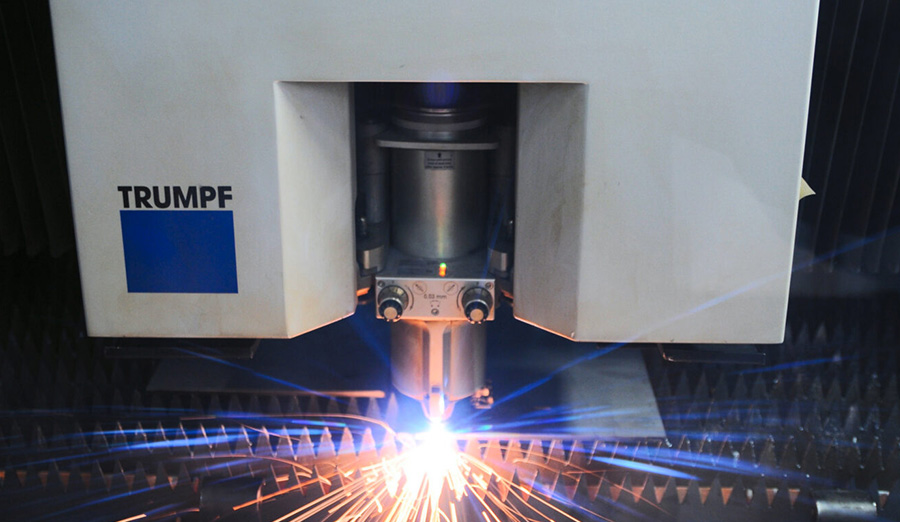

CNC laser cutting is the use of a centred and high-powered beam laser when cutting materials with excellent accuracy. The use of a computer controlled device guides the laser for following the design pattern to cut through materials including metals, plastics, wood or glass. This method is useful in its ability to create complex geometries close tolerance without touching the fabric thus reducing fabric damage. CNC Laser cutting service provides clean, easy cutting edges hence eradicating the need for additional operations in many circumstances.

Benefits of CNC Laser cutting

- Precision: Capable of cutting extremely particular styles.

- Versatility: Appropriate for numerous materials and thicknesses.

- Performance: Faster production with minimum material wastage.

- Cost-effective: Reduces labour charges by using automated approaches.

What is CNC Punching work?

CNC Punching work is another extraordinarily efficient fabrication method that makes use of a punch press to create holes or particular shapes in sheet materials, generally metallic. The punch press is managed through a CNC system that ensures actual positioning and repetitive accuracy. This method is right for developing elements with repetitive patterns or multiple holes, including perforated panels, metal enclosures, and different business additives. CNC punching is distinctly effective in handling thicker materials and large production volumes while keeping tight tolerances.

Benefits of CNC Punching

- Speed: high-speed punching with constant accuracy.

- Cost-Efficiency: Best for high-volume manufacturing.

- Flexibility: Capable of managing numerous thicknesses and material types.

- Durability: Creates strong, long-lasting components.

Bottom line

Every single piece of work that comes out of CNC laser slicing and CNC punching from Sharan Elecmech is as precise, versatile, and efficient as modern manufacturing demands. Regardless of whether for complicated geometries or for high-volume production, these providers enable industries to provide excellent, made-to-measure components necessary to satisfy the demands of today’s aggressive sectors. An application of this technology will enable producers to earn faster instances of manufacturing, minimal wastage of materials, and quality high-level outcomes for their work.